Automatic carton management

At Wiba Automation, we are dedicated to providing highly efficient and high-quality solutions that address the unique challenges faced by our customers in the plastics industry. Through our tailor-made automated carton buffer solutions, we strive to optimize your packaging process in a way that enables increased production speed, reduced production costs and a significant increase in staffing flexibility.

With creativity, technical knowledge and industry-specific expertise, we tailor solutions that not only meet your current needs but also position you for future success. By investing in Wiba Automation’s automated carton buffer solutions, you gain access to a sophisticated and reliable partner that strives to maximize your production operations in a cost-effective manner.

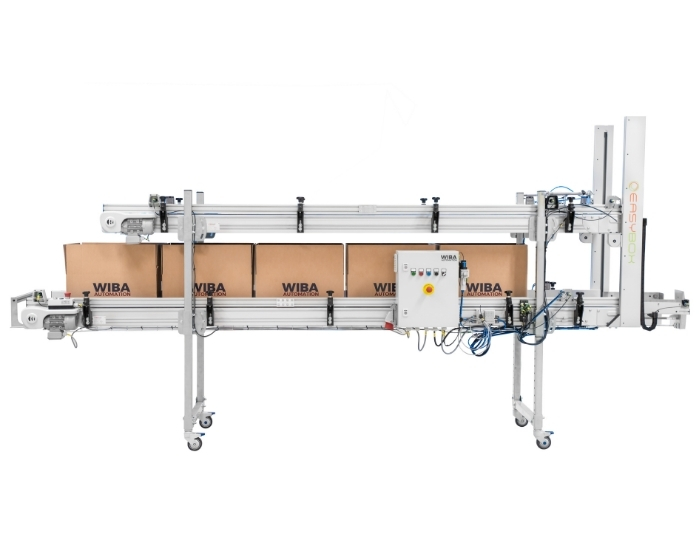

FilaBox - Electric carton buffer

FilaBox is a fully automatic carton buffer for placing parts in cartons by robot. The carton buffer is flexible, the number of belts and length of the belts can be adjusted depending on the desired time to run unmanned. The size of the belts is adaptable to the dimensions of your cartons. Control is via robot with inputs and outputs or integrated HMI filabox. Lifting of boxes/cartons is done electrically and the total weight must not exceed 100 kg. FilaBox can be purchased as "stand-alone" to your existing machine or in a complete automation cell.

EasyBox - Pneumatic Cardboard Buffer

EasyBox is an advanced conveyor belt solution for automatic box handling, perfectly integrable in both new and existing robot-controlled cells. The control can be managed via robot with inputs and outputs or the integrated HMI easybox. The lifting of the box/carton is pneumatic, and the maximum capacity is 20 kg (for heavier products we recommend FilaBox, the larger version of EasyBox). The number of belts, width and length are flexible and can be adapted to your exact requirements.

Optimize your production process with EasyBox - a reliable and flexible solution that gives you control and precision in your packaging management.

EasyBox - Medical - Specially adapted for cleanroom environments

Our EasyBox medical is designed for automatic carton handling in cleanroom environments. It is easily integrated into both new and existing robot-controlled cells. Control is via robot with inputs and outputs or via the integrated HMI easybox. The lifting of the box/carton is done electrically, and the maximum weight is limited to 20 kg. Adaptability extends to the number of belts, width and length, all adjustable to meet your exact requirements. For cleanrooms and the food industry, we also offer the option of approved oils.

Optimize your production process with EasyBox - a reliable and flexible solution that gives you control and precision in your packaging management.

Get in touch!

Telephone

Office

Depågatan 7

334 33 Anderstorp